Detect underperformance faster

Underperformance detectable from mode gain can cost up to 5% of energy capture

Simply put, mode gain is the ratio of the generator torque and the square of the generator speed:

\[\text{mode gain}=\frac{\text{generator torque}}{(\text{generator speed})^2}\]In many cases, this is calculated from 10-minute mean values and the torque itself may be calculated from the ratio of 10-minute mean power output and generator speed, and may also be adjusted to correct the effect of air density. So, why calculate this metric? This requires delving slightly into rotor aerodynamics and the basics of wind turbine control theory.

The power coefficient (i.e. aerodynamic efficiency) of a wind turbine rotor, in a given state of erosion and dirtiness, is primarily a function of only tip-speed ratio (the ratio of the rotor’s tip speed to the wind speed) and pitch angle. It follows that there exists a tip-speed ratio and pitch angle of maximum efficiency. Therefore, below rated power and maximum rotational speed, the turbine’s controller intends to operate the turbine at the optimal tip-speed ratio and pitch angle.

How do we identify optimal mode gain?

From the aerodynamic and mechanical relationships, it follows that in order to maintain a particular tip-speed ratio over varying wind speeds, the generator torque should be proportional to the square of the generator speed. The value of the constant of proportionality determines the tip-speed ratio you end up operating at.

When the turbine is following this relationship to track the optimal tip-speed ratio, we call this the “optimal mode” with the constant of proportionality being the “optimal mode gain”. However, in performance monitoring, we often do not have the information to know if this mode is optimal and hence refer to this ratio as the “mode gain”.

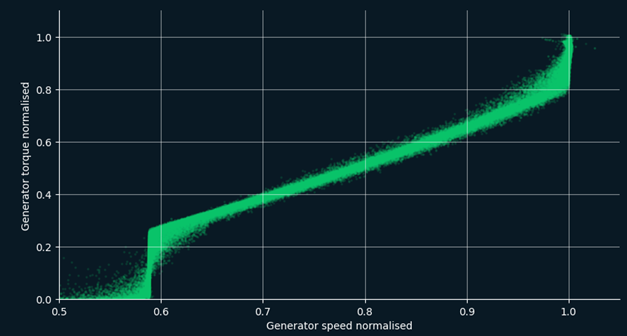

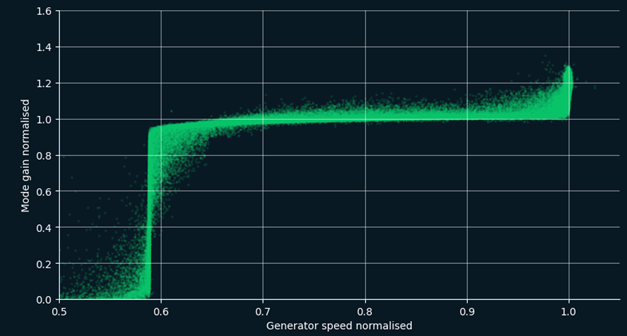

A snapshot of the generator torque-speed relationship in normal operation for a typical modern turbine.

The middle, variable-speed part of the relationship is where the turbine is tracking a constant tip-speed ratio.

Why does this matter?

Simply put, if the turbine’s observed mode gain changes over time, then at some point it has been operating below the optimal tip-speed ratio and has therefore lost efficiency. Our aim is to highlight if changes occur over time or different turbines are controlled differently, and question those changes and ensure that they are in the interest of the asset owner. Such changes in performance may be hard to measure or detect through a nacelle anemometer power curve but could nonetheless be costing up to 5% of energy capture, adding up to significant value over time.

Bitbloom monitors mode gain in partial load as part of the out-of-the-box analytics in the Sift Monitor Insights product.

Portfolio Generation Improvement Software

Find Out More

Sift Monitor increases energy yields, improves performance, aids in condition monitoring and lowers renewable asset risk.