Sift Monitor Managed

Deploying its “Sift Monitor Managed” monitoring service, Bitbloom monitors a wide range of critical operations metrics ranging from data quality, availability, operating efficiencies, main component condition via temperature and oil particle levels, structural vibrations, curtailment strategies, and more.

Data is collected from Cubico’s 2nd level SCADA system and automatically cleaned, enhanced, and analysed through a wide range of models and algorithms. Outliers, deviations, changes in trends, and other issues which may be cause for concern are automatically detected and alerted. Bitbloom’s expert analysts closely track these metrics and raise issues which require attention directly with Cubico’s asset management teams within the Sift Monitor platform.

A Quote from Diego Kieffer, Asset Manager, Cubico Sustainable Investments

“Bitbloom’s monitoring tools have been a valuable addition to our asset management capabilities. Their data-driven insights help us detect potential issues earlier and more reliably than traditional turbine alerts alone, allowing us to proactively plan replacement and significantly reduce costs and downtime.

“For a business like ours, operating across multiple markets with a clear focus on asset performance and optimisation, scalable solutions like Bitbloom’s give us both the confidence and clarity we need to act early and make smarter decisions.”

Diego Kieffer, Asset Manager, Cubico Sustainable Investments

Normal Behaviour Models

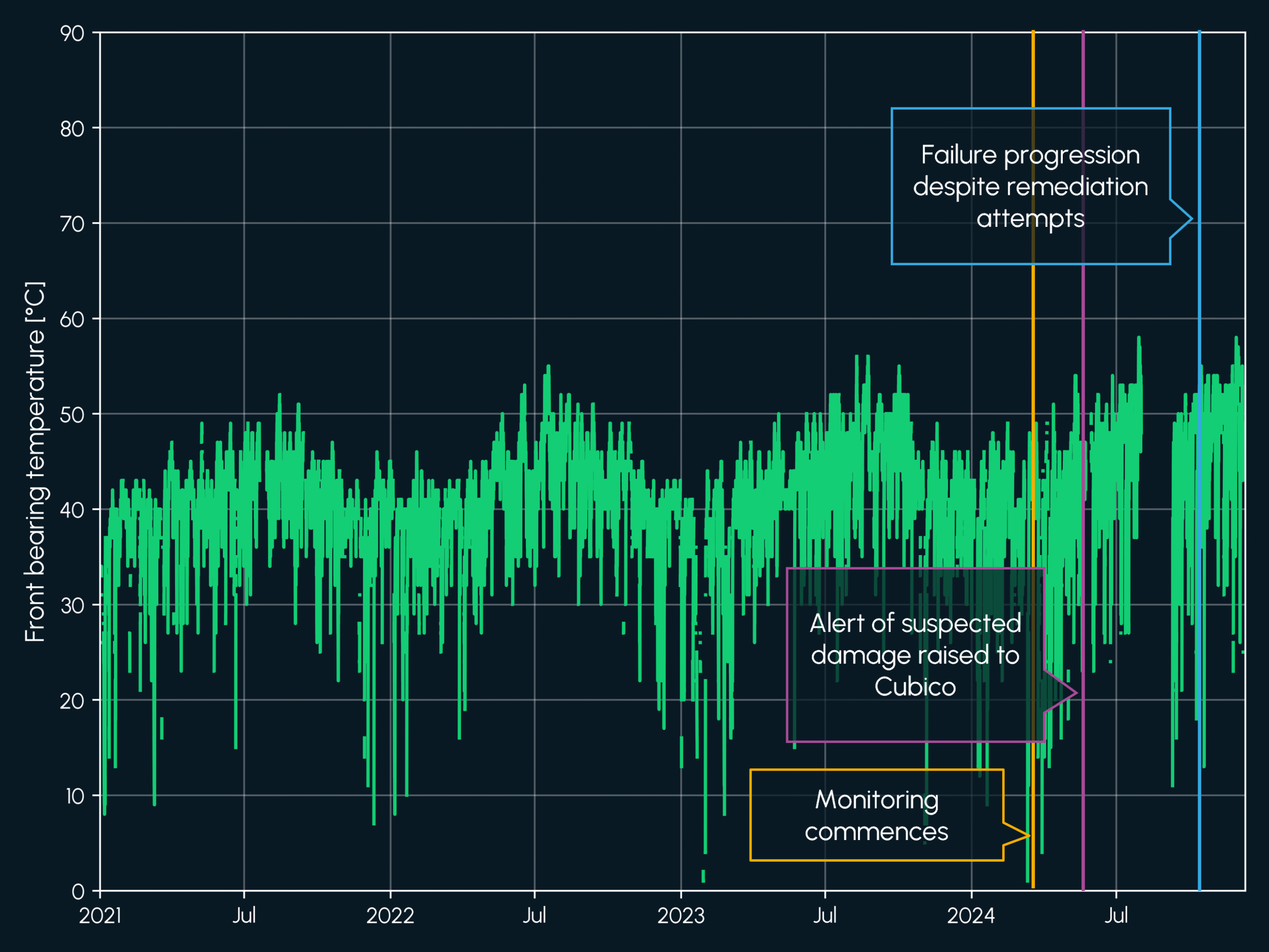

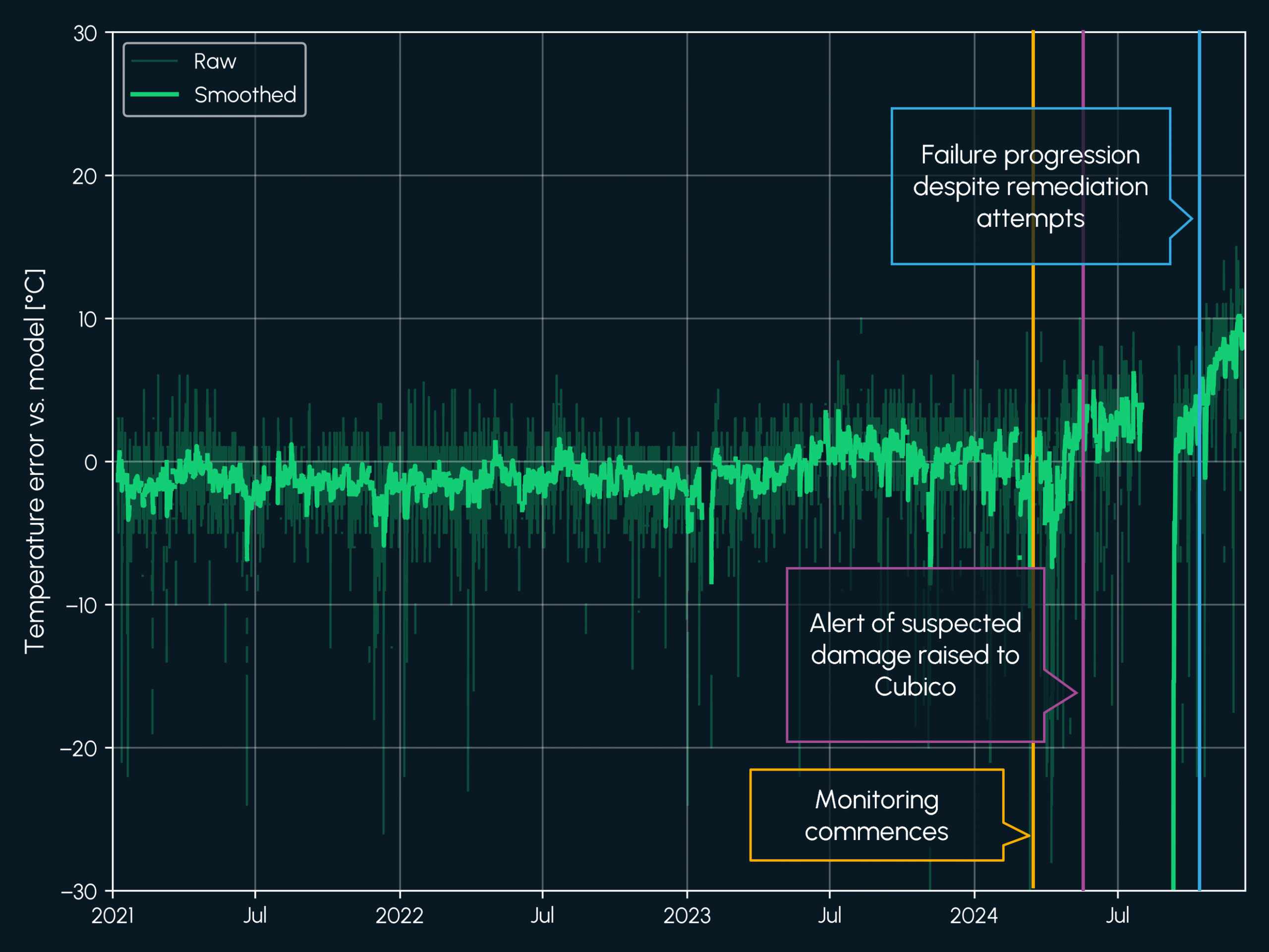

One aspect which is monitored is the main bearing health via temperature-based normal behaviour models (NBMs).

NBMs are a relatively common machine learning method, where historical data is used to train models on the “Normal Behaviour” of a system’s response in relation to some external conditions. In this case, the measured bearing temperatures are compared to those expected by the NBM, given influencing factors such as power and ambient temperature, to derive an error signal. The error signal is analysed by statistical methods to derive a proxy of the health of the system.

Increased main bearing temperature

Shortly after commencement of the monitoring of a new wind farm integrated into Cubico’s portfolio, Bitbloom highlighted increased main bearing temperature at one specific turbine.

The temperature change was relatively subtle and significantly lower than the built-in turbine controller safety thresholds, which would otherwise trigger warnings within the turbine’s event data. The temperature anomaly therefore remained undetected within the main SCADA system.

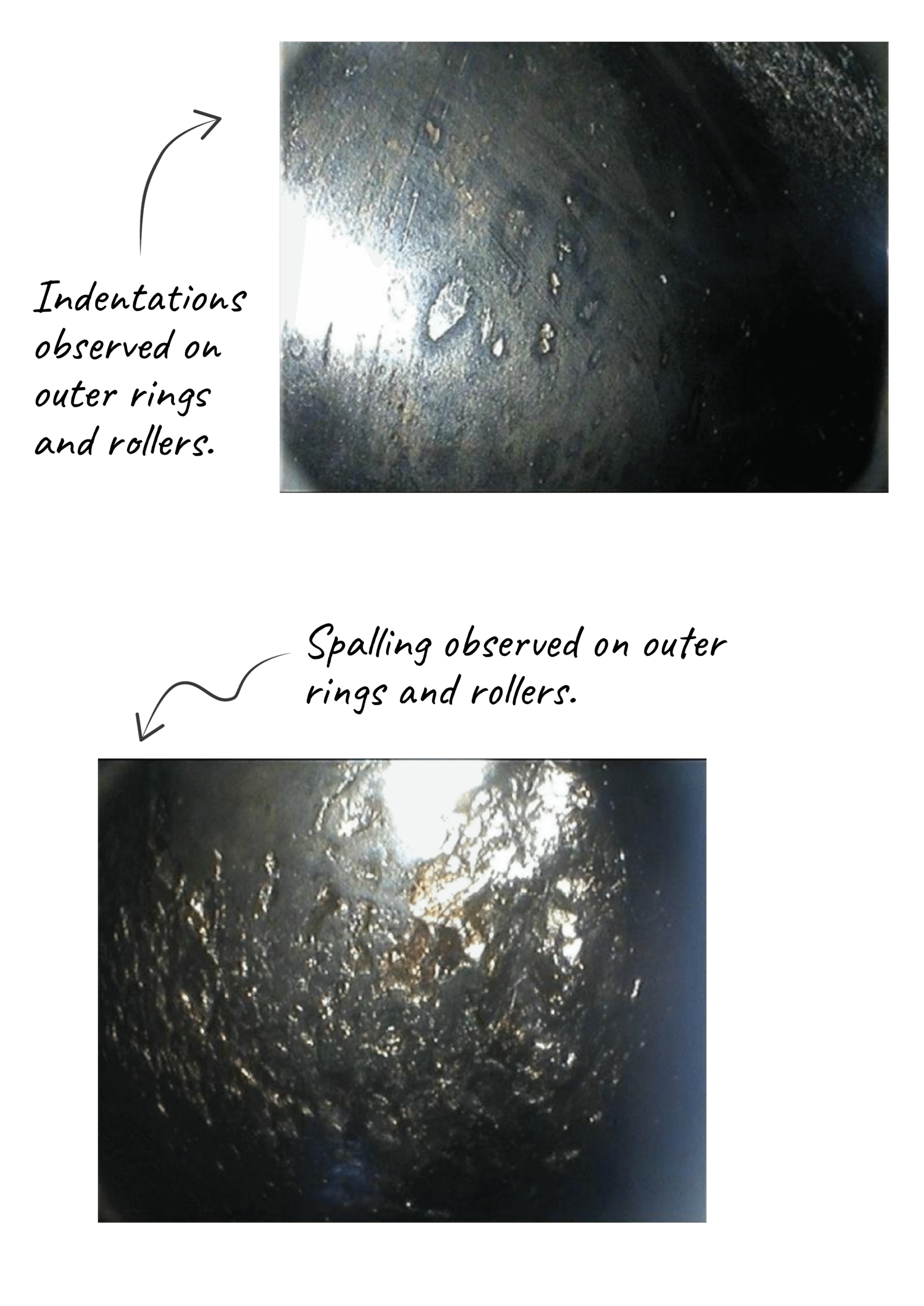

Inspecting the bearing

Following the identification of the potential main bearing temperature increase based on the NBM monitoring technique, Cubico requested that the service provider inspect the bearing.

An initial attempt at improving grease management was made, however continued monitoring by Bitbloom quickly proved that this was insufficient and that temperatures remained elevated. The service provider was requested to re-visit the turbine and complete a thorough inspection.

Main bearing damaged confirmed

Upon inspection, the main bearing was found to suffer from spalling, scratch lines and indentations , and required replacement.

It was, however, deemed that the turbine may continue to operate at full power for several months, giving sufficient time to organise spare parts, tooling, and wait for suitable weather window to undertake the replacement.

By proactively monitoring drivetrain temperatures, failures can be detected well before a turbine’s built-in safety limits trigger an emergency shutdown. This allows for planned maintenance, cutting costs and minimizing downtime.

See images on the left for Indentations (top) and spalling (bottom) observed on outer ring and rollers.

The cost difference

Main bearing failures are always costly to remedy, but having advance notice can drive huge savings of €100k to €300k or more.

- Urgent delivery of a main bearing can increase the cost of the part by around 20% to 50%, compared to having a 3–6 month available lead time.

- Tooling costs, in particular crane mobilisation costs at short notice, generally attract a high cost premium, which may add 50% to 100% to tooling costs.

- The biggest benefit however often comes from avoiding extended downtime. Waiting for spare parts, tools, staff, suitable weather windows, and in some cases completion of required civil works, can lead to several months of downtime. With months of advance notice from failure prognostics, downtime can be limited to a few days.

Conclusions

By using third-party monitoring experts Bitbloom, Cubico is proving that its strategy to invest in smart solutions is delivering on their ambition to maximise the value and profitability of its assets.

Temperature monitoring has both benefits and drawbacks compared to more classical vibration-based CMS systems: While CSM systems are often able to detect failures earlier and can classify the type and severity of the failure, temperature-based methods can be deployed across a wider set of components within the turbine and, crucially, can be scaled at low cost across entire portfolios.

If you would like to learn more about how your organisation can benefit from cost-effective automated monitoring of you assets, don’t hesitate to book a meeting with us. Visit out knowledge hub for more case studies, webinars, and general information on how we generate insights from data.